Common Pumping Liquids

Mvura yakachena

Kuunza ese epombi yekuyedza macurves kune yakajairwa base, maitiro epombi anobva pamvura yakachena pane ambient tembiricha (kazhinji 15 ℃) ine density ye1000 kg/m³.

Zvinhu zvinonyanya kuzivikanwa pakuvaka kwemvura yakachena ndeyese simbi yekuvaka kana cast iron casing yakasungirirwa mukati mebronze, Pakupomba mvura yakachena, kana mvura inotsanangurwa zviri nani seyakarerekera ine chaiyo giravhiti ye1 isina solids iripo,kupera kusveta pombiuye horizontalkupatsanura casing pombidzinonyanya kushandiswa. Kana misoro yekubuda yakakwira ichidikanwa, mapombi emhando dzakawanda anoshandiswa.

Kana vagadziri vakaganhurirwa nzvimbo yepombi yemba, vertical units yeimwe yakasanganiswa kuyerera, axial kana turbine mhando pombi dzinoshandiswa.

Mvura yegungwa sechinhu chinoparadza

Mvura yegungwa ine munyu wose unosvika 25 g/ℓ. Inenge 75% yemunyu ine sodium chloride NaCl. Iyo pH-kukosha kwemvura yegungwa kazhinji iri pakati pe7,5 ne8,3. Mukuenzana nemhepo, iyo oxygen yemukati pa15 ℃ ingangoita 8 mg/ℓ.

Degassed mvura yegungwa

Mune zvimwe zviitiko, mvura yegungwa inobviswa makemikari kana physic-ally. Nekuda kweizvi, hutsinye hunoderera zvakanyanya. Panyaya yemakemikari degasification, inofanira kuonekwa kuti degassing inotora nguva. Nokudaro, zvakakosha zvikuru kuti kushandiswa kwe degasification, kureva kubviswa kweokisijeni, kunopedzwa zvakakwana mvura yegungwa isati yapinda pombi.

Kuchengetedza kunofanira kuitwa mukushanda-kubhururuka kunogona kuitika kuburikidza nekuputika kwemhepo. Kunyange zvazvo inrushes ine nguva shoma-yakachenjera, kukanganisa kwezvinhu zvinogona kukurumidza kuitika mune mamwe mamiriro ezvinhu kana kuvapo kweokisijeni kusingatariswi kana zvinhu zvasarudzwa. Kana inrushes yeokisijeni isingagone kubviswa panguva yekushanda kwepombi, zvinofanirwa kufungidzirwa kuti mvura yegungwa ine oxygen.

Mvura ine brackish

Izwi rokuti 'brackish water' rinoreva mvura yakachena yakasvibiswa zvakasimba nemvura yegungwa. Nezvekusarudzwa kwezvinhu, mirairo yakafanana inoshanda pakutakura kwemvura ine brackish semvura yegungwa. Mukuwedzera, mvura ine brackish kazhinji ine ammonia uye/kana hydrogen sulphide. Kunyange kuderera kwe hydrogen sulfide, kureva munharaunda yemamirigiramu mashomanana parita, inokonzera kuwedzera kwekuwedzera kwehasha.

Mvura yegungwa kubva pasi pevhu

Mvura yemunyu inobva pasi pevhu kazhinji ine munyu wakanyanya kudarika mvura yegungwa, kazhinji inenge 30%, kureva kuti pasi pemuganho wekunyungudika. Pano zvakare, munyu wakajairika ndiyo inonyanya kukosha. Ukoshi hwepH hunowanzo dzika zvishoma (kudzika kusvika pa4), kureva kuti mvura ine acidulous. Nepo zviri mukati meokisijeni yakadzikira kana kuti haipo, H₂S yemukati inogona kuita mazana mashoma emamirigiramu parita.

Mishonga yakadai yemunyu ine H₂S inokanganisa zvakanyanya uye inodaidzira zvinhu zvakakosha.

Nekuda kwehuwandu hwemunyu uye zvinoenderana nemamiriro ekushanda, munhu anofanira kutarisira imwe dhigirii yekunaya kwemunyu. Mumamiriro ezvinhu akadaro, matanho akakodzera anofanirwa kutorwa maererano nekugadzirwa, kushanda uye kusarudzwa kwezvinhu.

Corrosion mumvura yegungwa

Zvishandiso zvakashandiswa hazvingoratidzi kushomeka kwepamusoro kwakakwanirana kune yunifomu, asiwo kurwisa ngura yemunzvimbo kunyanya gomba uye kukoromoka. Zviitiko zvekuora zvakadaro zvinosangana kunyanya nekuzvipfuudza ferro alloys (stainless steels). Mapombi anodaidzwa kuti 'standby', ayo anongoshandirwa nguva nenguva, anokonzera njodzi yekumira kuita ngura; mafashamo nemvura yakachena nguva isati yavhara kana kutanga-nguva kunoonekwa kunobatsira.

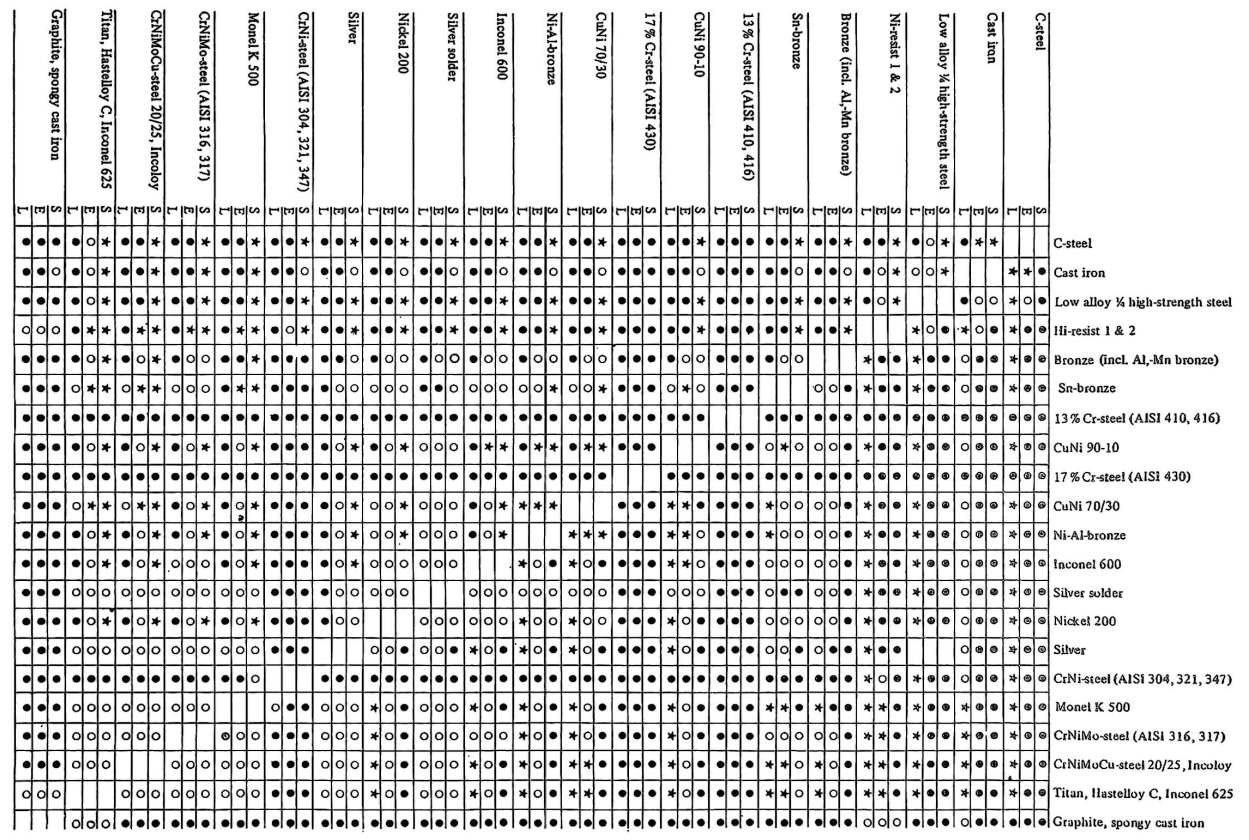

Izvo zvakasiyana-siyanapombi yemvura yegungwazvikamu zvinofanira kugadzirwa kubva kuzvinhu zvemhando imwechete kuitira kudzivirira galvanic corrosion. Musiyano unokwanisa pakati pezvishandiso zvega ndewekuve wakaderera sezvinobvira. Zvisinei, kana zvinhu zvakasiyana-siyana zvichifanira kushandiswa nokuda kwezvikonzero zvekugadzira, nzvimbo dzesimbi dzisina kunaka dzakasangana nemvura dzinofanira kunge dzakakura kana dzichienzaniswa nedzakanaka. Mufananidzo 5 unopa ruzivo pamusoro pengozi yegalvanic corrosion kana zvinhu zvakasiyana-siyana zvakabatanidzwa.

High velocities inogona kukonzera kukukurwa kwevhu. Mhedzisiro yacho inova yakakomba zvakanyanya, iyo inowedzera hutsinye hwepakati, uye inokwirisa kukurumidza kwayo. Nepo mwero wekuyerera uchikanganisa hunhu hwesimbi dzisina tsvina uye nickel alloys kune diki dhigirii chete, chinzvimbo chinodzoserwa uko izvo zvisina kusanganiswa ferrous zvinhu uye copper alloys zvinobatanidzwa. Mufananidzo 6 inopa ruzivo rwehutano pamusoro pesimba rekuyerera kwemazinga. Kufunga kwakakodzera kunofanirwa kupihwa nekudaro kuti svikiro ine oxygen kana H₂S. H₂S yakakura yakawanda inowanzobvisa kuvapo kweokisijeni; mumamiriro ezvinhu akadaro, iyo yepakati inenge iine acidulous zvishoma, kusvika kupH ye4.

Maitiro enyama

Tafura 1 inoita kurudziro yezvinhu zvepombi kana musanganiswa wavo. Kunze kwekunge zvataurwa neimwe nzira, ruzivo rwunotevera runoshanda kumvura yegungwa pasina chero H₂S yemukati.

Simbi isina kuiswa uye simbi yakakandwa

Simbi isina kuvharwa haina kukodzera kumvura yegungwa, kunze kwekunge ichipiwa nejira rakakodzera rekudzivirira. Simbi yakakandwa inongoshandiswa kune yakaderera velocities (inogoneka kune casings); mune iyi kesi yakajairika cathodic kuchengetedza yevamwe vemukati inofanira kushandiswa.

Austenitic Ni-castings

Ni-Resist 1 uye 2 yakakodzera chete yepakati velocities (kusvika kunosvika makumi maviri m/s).

Galvanic Corrosion Mumvura yeGungwa Pa5-30 ℃

Nguva yekutumira: Mar-11-2025

sales@tkflow.com

sales@tkflow.com