Kuchengeta vharafu yekubuda yakavharwa panguvaMapombi eCentrifugaloparesheni inounza njodzi dzakawanda dzehunyanzvi.

Kusadzora kutendeuka kwesimba uye kusaenzana kwe thermodynamic

- 1.1 Pasi peiyo yakavharwa mamiriro ekuvhiya kwepakati tembiricha, rinenge rese rekuisa simba rinoshandurwa kuita kupisa simba. Iyo yepakati haikwanise kubvisa kupisa, zvichiita kuti tembiricha iri mukamuri yepombi ikwire zvakanyanya. Kuenderera mberi kwekushanda kuchaita kuti vaporization yepakati, ichimhanyisa iyo carbonization yezvinhu zvekuisa chisimbiso.

1.2 Chisimbiso system kukundikana Munharaunda yekupisa kwakanyanya uye vaporization yepakati, iyo mechanical chisimbiso inovimba nekuzora uye kutonhora kwepakati inotungamira mukutadza kwayo kupisa - iyo mechanical chisimbiso ichava nekukakavadzana kwakaoma uye chisimbiso chiso chichapiswa.

Abnormal mechanical stress

- 2.1 Axial force overrun The axial force yevhavha yekuvhara inowanzoita 1.5-5 nguva iyo yemamiriro ekushanda akajairika, uye kutakura kwekutakura mutoro kunogona kusvika kana kutopfuura muganhu wayo wekutakura, zvichiita kuti kupatsanurwa kwebheji rinotakura kana kuti deformation yekeji.

2.2 Kuzununguka uye kukuvadzwa kwekuneta Musiyano wekuwedzera kwekushisa kunokonzerwa nekupisa kwakanyanya kunotungamirira kumhepo inopisa kana kupisa kunetseka, kukanganisa kusina kunaka pakati peimpeller uye pombi yepombi, uye simba rekusagadzikana kwe hydraulic load, iyo inokonzera kuti simba rekugadzirisa rotor riparadzwe, kuzununguka kunowedzera, uye zvikamu zvakakuvadzwa kuneta.

Cavitation uye kukuvara kwezvinhu

3.1 NPSH allowance inverted medium vaporization [ita kuti cavitation allowance (NPSHa) yemudziyo idzike pane inodiwa NPSHr yepombi], ichigadzira mabhuru, uye kuvhunduka kunokonzerwa nekudonha kwemabubbles kunogona kusvika ku690MPa, zvichiita kuti pitting uye uchi kuparara kwe impeller runner.

3.2 Metallographic chimiro kuderera Kune austenitic Stainless simbi impellers, sensitization inogona kuitika munzvimbo yepamusoro tembiricha, uye intergranular corrosion rate ichawedzera uye kusimba kwesimba kunoderera. Kune carbon steel impellers, matambudziko pakupisa kwepamusoro anonyanya kukosha, zvakadai sepamusoro-tembiricha oxidation uye decarburization, zvichiita kuti kuderera kwesimba repamusoro uye mitemo yakawanda; Kana iine tsvina yakadai sesarufa uye phosphorus, zviri nyore kuparadzanisa pamiganhu yezviyo pakupisa kwakanyanya, zvichiita kuti kupisa kwemafuta uye kuputika nyore panguva yekushanda; Pasi penguva refu tembiricha yakakwira, kabhoni simbi ine kushomeka kwekudzivirira, uye tembiricha yepamusoro yemuno inogona kusimudzira creep deformation, iyo inozopedzisira yatungamira kune impeller kuputsika kana kuneta kutadza.

Kuchengetedzwa kwehurongwa uye njodzi dzehupfumi

4.1 Kumanikidzwa kwekumanikidzwa kwegomba rinomanikidza rinopfuura muganhu uye kushanda kwevhavha yekuvhara kunoita kuti kubuda kwepombi kusvike 120-150% yehuwandu hwehuwandu, uye kune ngozi yekupaza kuburikidza nekumanikidzwa kwakaiswa kwevhavhavha yekudzivirira, iyo inogona kukonzera kusununguka kwekudzivirira kusunungurwa kana kuputika kwepombi weld.

4.2 Kushandiswa kwesimba uye mari yekugadzirisa kuwedzera kwevhavha yekuvhara kushanda ndiyo "muurayi mamiriro" emapombi ecentrifugal, ayo anowedzera zvakanyanya kushandiswa kwesimba munguva pfupi, uye kushanda kwenguva refu kuchaita kuti kukuvadzwa kwakashata kune zvigadzirwa, uye mari yakawanda yekuchengetedza inogona kuwedzera ne3-10 nguva.

Kuderera kwemamiriro ekushanda enhau

Kune midhiya inoputika (semuenzaniso, LPG), kushanda kwevharuvhu yakavharwa kuchawedzera vaporization yechikamu chemvura, uye gasi-mvura-yeviri-yechikamu inoyerera mukamuri yepombi inokonzera kamwe kamwe kuyerera kushanduka, zvichikonzera periodic oscillations yeaxial masimba uye kukurumidza kupfeka kwezvikamu.

Indasitiri ruzivo uye mwero zvinodiwa

6.1 Chiitiko cheindasitiriMaererano neruzivo rwechishandiso cheinjiniya, nguva yekumhanya yevharuvhu yepombi yecentrifugal haifanire kudarika maminetsi maviri, uye kazhinji inogumira kuminiti imwe. Zvinokurudzirwa kumisikidza interlock control system kuti iite otomatiki chirongwa chekudzivirira chekuvhara kana valve yekubuda ichivhara uye nekuwedzera nguva.

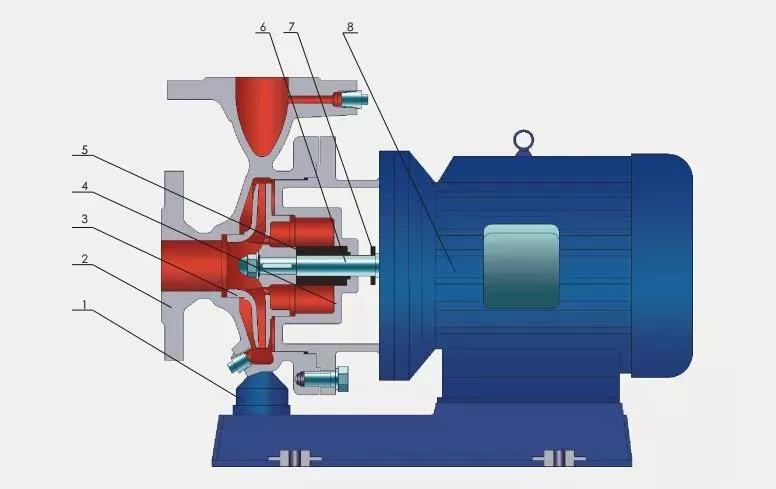

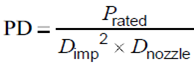

6.2 Mamiriro ezvinhu anoda kuti API 610 12th Edition yakajairika inotaura kuti mamwe mapombi ane simba guru, akabatanidzwa kana akawanda ane kukurumidza kupisa kwekushisa kana valve yekubuda yakavharwa, izvo zvinoita kuti kuedza kusagoneke uye / kana kusachengeteka kana valve yakavharwa. Kukwira kwetembiricha kwakabatana zvakanyanya nekuwanda kwemagetsi. Simba density PD, iyo inogona kuenzaniswa se:

P yakayerwa: Chiyero chesimba padanho kana mvura iri muhp (kana MW)

D imp: Yakatemerwa impeller dhayamita mukati. (kana m)

D nozzle: Nominal outlet flange dhayamita mukati. (kana m). Kune-kusveta kaviri, imwe-nhanho pombi, iyo D nozzle ndiyo inlet flange dhayamita.

Iyo yakajairika yakakosha kukosha kwePD ndeye 0.286 hp/in.3 (13 MW/m3), kupfuura iyo inokurudzirwa kuti isamhanye pombi nevhavha yekubuda yakavharwa panguva yekuyedzwa kwekuita.

Nguva yekutumira: Jun-04-2025

sales@tkflow.com

sales@tkflow.com